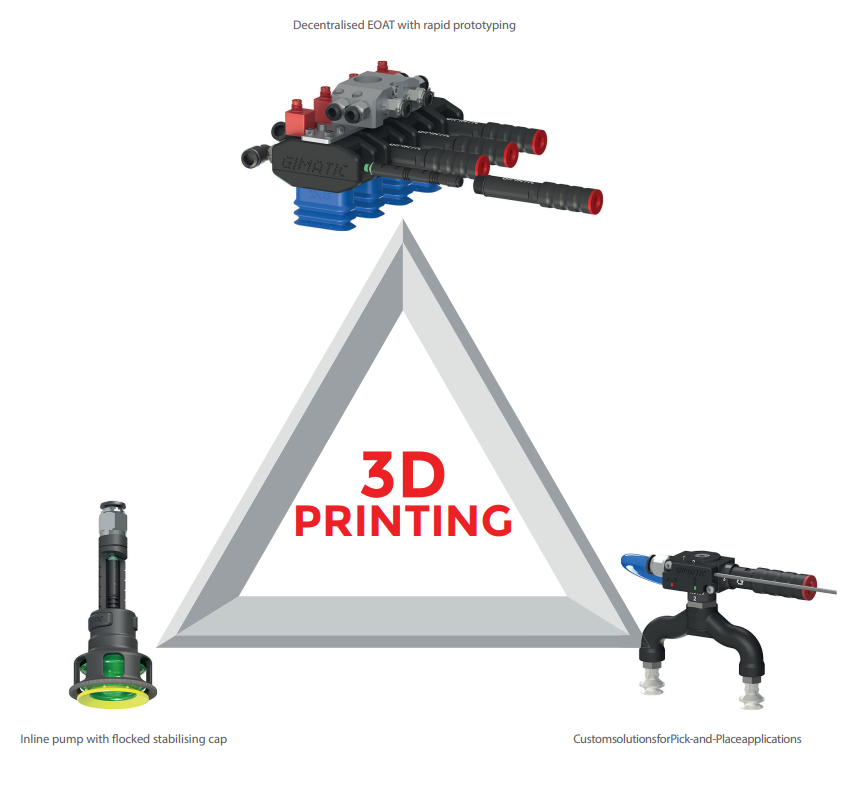

Customised Solutions

3D PRINTING

Following the demands of the market, Gimatic has equipped an area for 3D printing service with an HP Multi Jet Fusion system. Through a rapid prototyping service based on the customer's design, we are able to create completely customised gripping solutions that can meet the specific needs of the final customer. This technology makes products with PA12GB (Glass Beads) material, for greater rigidity, allowing our customers to receive products with low weight, high wear resistance and high quality. 3D-printed components can be flocked or fitted with rubber pads (HNBR) to provide a soft touch on the products to be handled. Threaded metal inserts are also available for mounting. 3L laser cutting and 3M metal working services are available.

| Material technical specifications | Method | |

|---|---|---|

| Material | PA12 Glass Beads | - |

| Density of the material | 1.3 g/cm³ | ASTM D792 |

| Tensile strength, max load | 30 MPa | ASTM D638 |

| Heat deflection temperature (@1.82Mpa) | 114°C | ASTM D648 Test Method A |

3M METAL WORKING

5-axis CNC machining service according to customer's drawing also for indivudual parts. Lead time: 5 working days.

Materials:

- Acetal resin (POM)

- Aluminium alloy (6000 series)

3L LASER CUTTING

Laser cutting and bending service according to customer's drawing also for individual parts (without minimum quantities). Lead time: 3 working days.

Materials:

- AISI 304 stainless steel (thickness: 1, 2 and 3 mm);

- Aluminium alloy 5754 (thickness 2, 3, 4 and 5 mm).

English

English